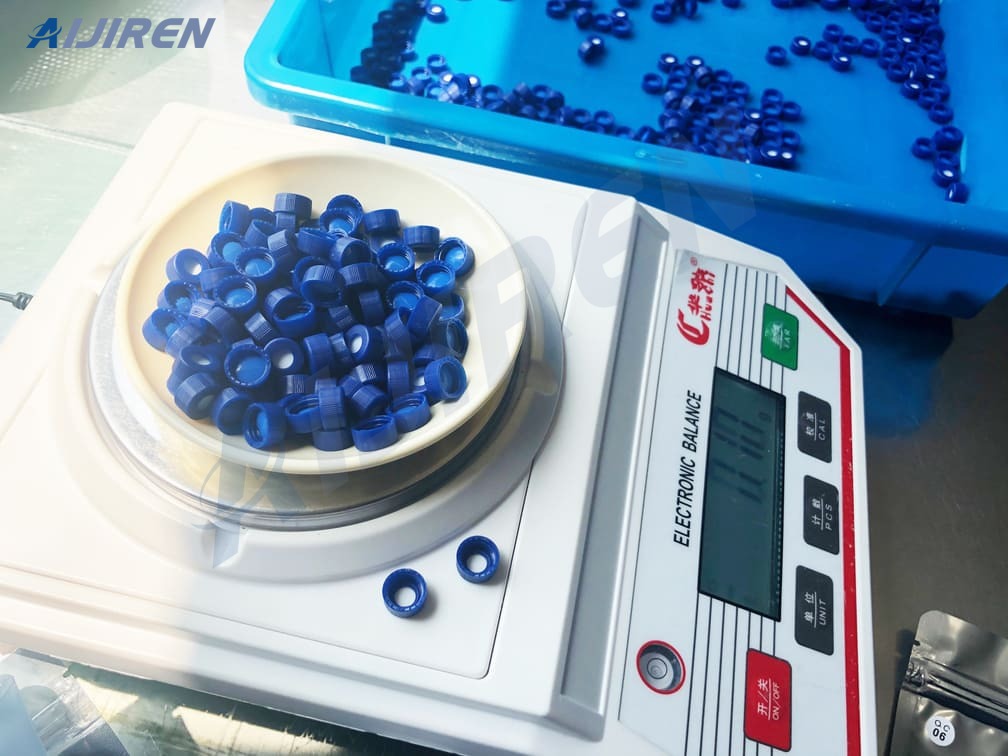

Septa of Autosampler Vial is Drying

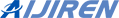

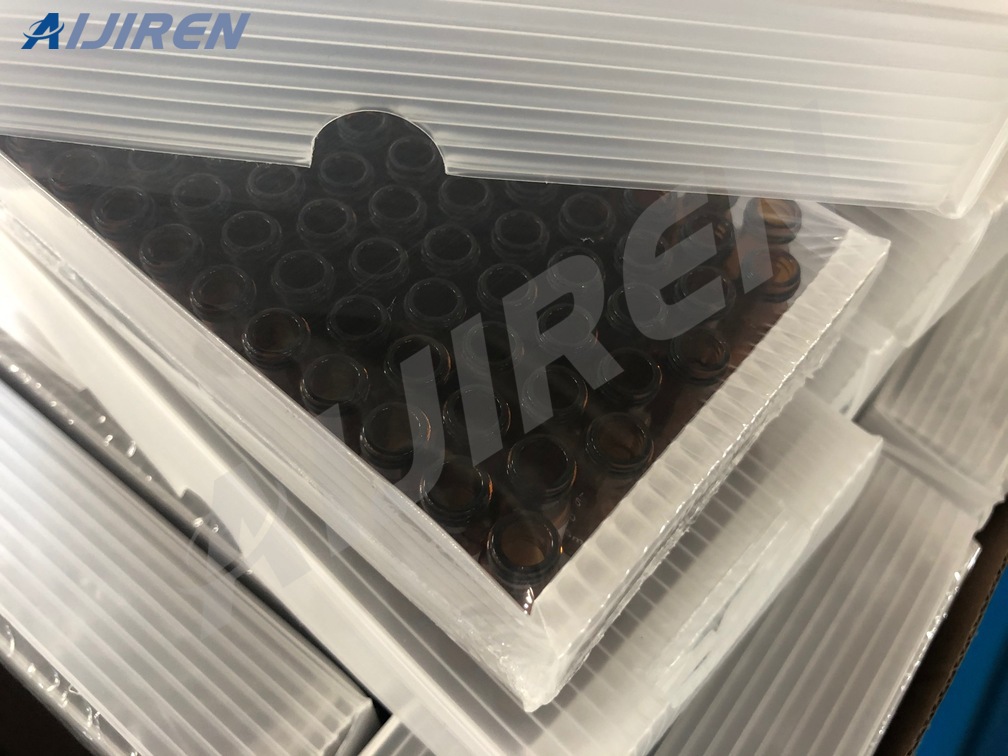

Aijiren uses Silicone and PTFE to produce Septa suitable for Autosampler Vial. Aijiren will compound PTFE and Silicone together in a binder-free compounding method. This Septa is softer and suitable for automatic injection needle puncture. Before laser cutting, there is a process, which is to dry in the dryer to dry the moisture in the raw materials, so as to ensure the texture and application of Septa.

Contact US

Get Price

Share:

Content

The silicone rubber/PTFE septa used by Autosampler Vial is designed to provide appropriate resistance to the autosampler needles during sample injection so that they can penetrate the sample vial correctly without damaging the septum or needle. If the needle resistance is too large or too small, it will damage the septum, affect resealing, block the needle due to the core of the septum material, and even damage the autosampler. The septa produced by Aijiren has good adaptability. For blunt needles, it is recommended to use Septa with pre-slit. If there are customers who want to know the chemical reagents applicable to Septa, the following figure lists the chemical compatibility of Septa materials.

|

Chemical Compatibility Overview |

|||

|

Chemical |

PTFE |

Silicone |

Butyl Rubber |

|

Acids, concentrated |

Excellent |

Poor |

Good |

|

Acids, dilute |

Excellent |

Good |

Excellent |

|

Air and gas permeability |

High |

Moderate |

Low |

|

Alcohols |

Excellent |

Excellent |

Good to excellent |

|

Aliphatic hydrocarbons |

Excellent |

Poor |

Poor |

|

Alkalis |

Excellent |

Good to excellent |

Good to excellent |

|

Aromatic hydrocarbons |

Excellent |

Poor |

Poor |

|

Halogenated solvents |

Excellent |

Poor |

Poor |

|

Ketones |

Excellent |

Poor to good |

Good to excellent |

|

Water |

Excellent |

Excellent |

Excellent |

Inquiry

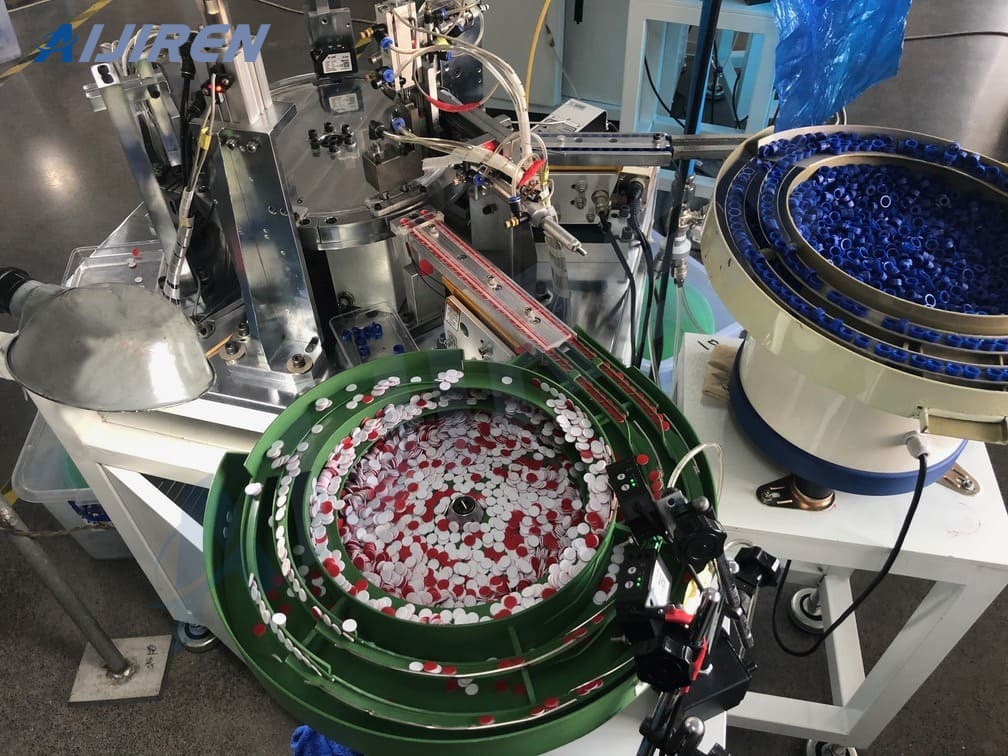

More Workshop