PTFE&Silicone Composite Material for HPLC Vial’s Septa

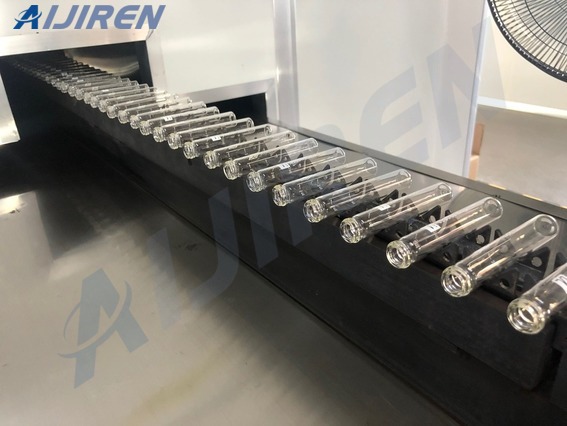

Aijiren presses Silicone and PTFE composite into the picture, and cuts them into rectangular sheets of similar size. Because PTFE is easy to curl and deform, the raw materials in the picture are all curled. Wait for it to enter the dryer to dry the moisture. Keep it level. Aijiren uses a mechanical laser to cut Septa, and guarantees the integrity and chemical nature of Septa.

Contact US

Get Price

Share:

Previous:

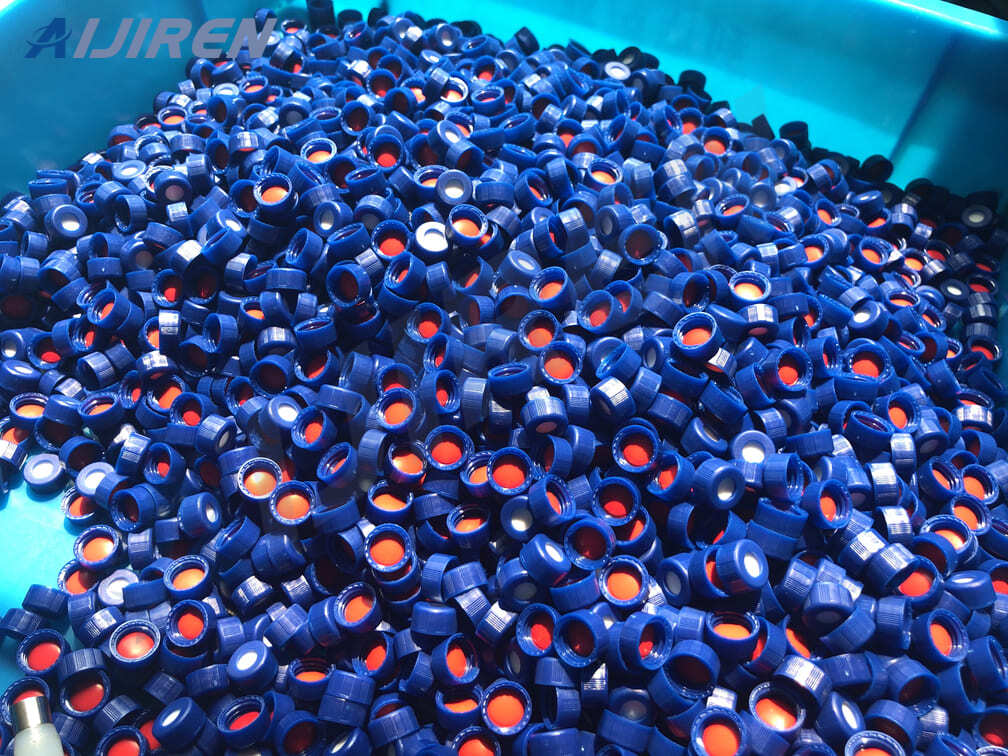

Mold Customization of Screw Neck Cap

Content

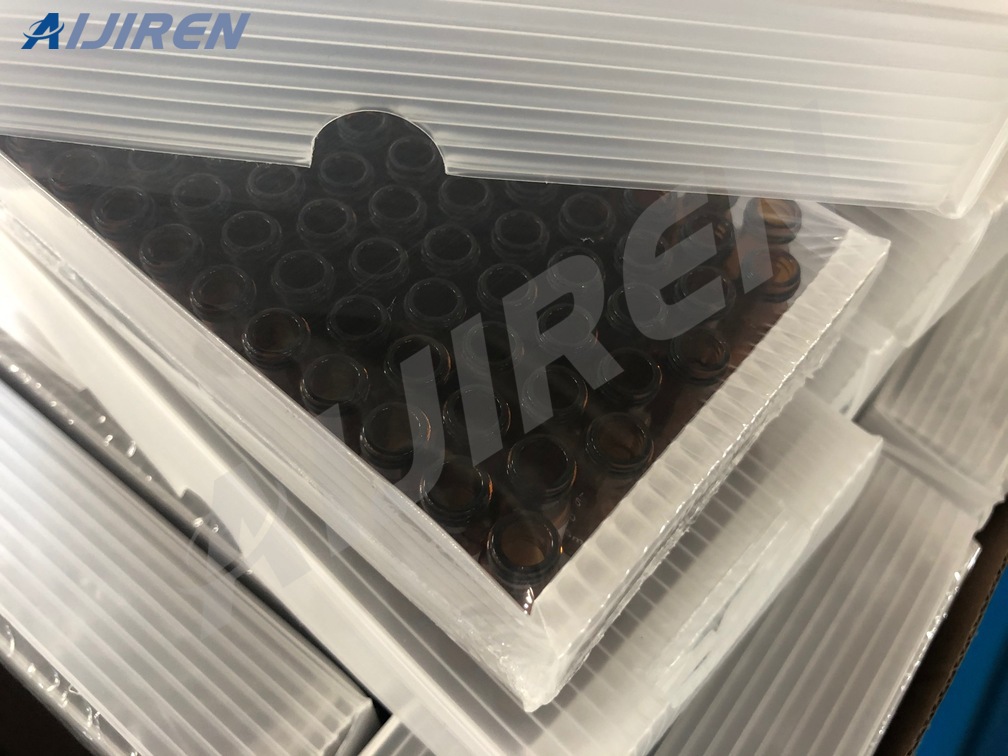

Aijiren produces matching Closures for HPLC Vials, especially Septa, which is made of Silicone and PTFE. Septa can ensure that the hplc vials are sealed. At the same time, it must ensure that the automatic injection needle can penetrate into the interior of Vias for sampling, so for Septa There are certain requirements for the thickness. Generally speaking, the thickness of Septa for different types of Vias and Cap is different. The thinner thickness is more suitable for puncture. If it is a large blunt needle, a pre-cut septum is required, but it is not suitable for repeated injections, otherwise it may fall into the bottle. The silicone septum has strong repetitive sealability, and can still maintain good airtight performance after puncture and injection; PTFE is a material with better chemical conditions at present, and can withstand strong acids and alkalis. The composite bottle of the two materials can be used for various laboratory purposes, such as sealed sampling, chemical storage, etc.

Inquiry

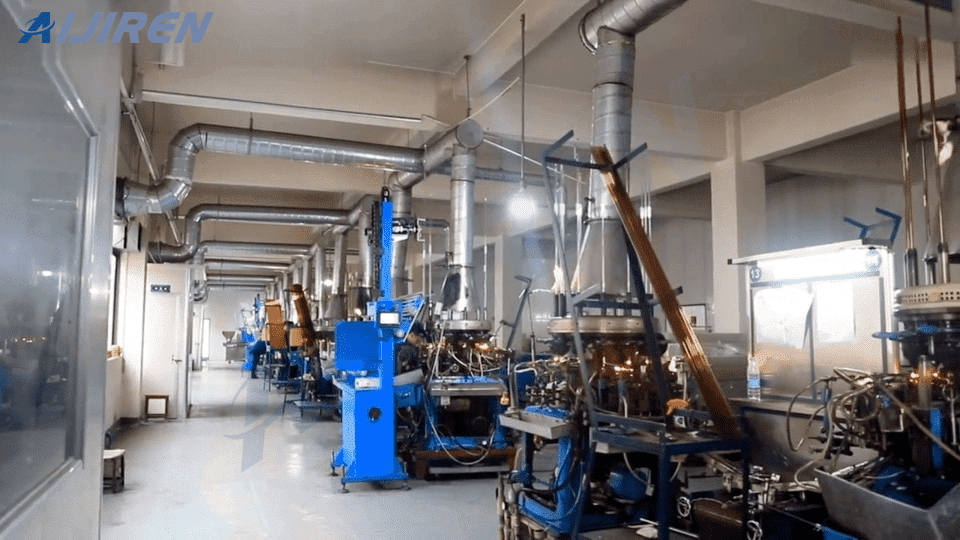

More Workshop