Combine 24mm Screw Neck Cap with Septa

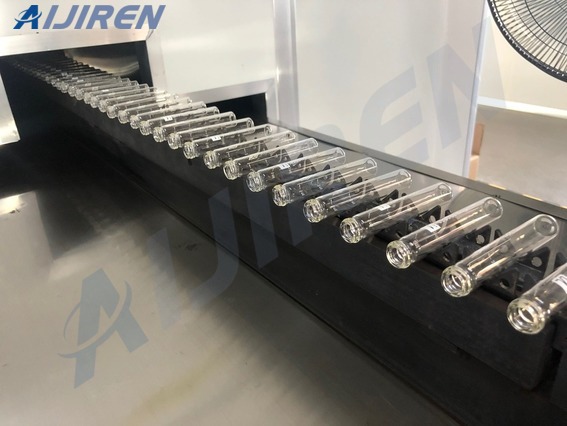

The worker of Aijiren shown in the picture is inserting a 22mm Silicone/PTFE Septa into a 24mm Screw neck Cap. The worker wears finger cots and holds a tool to press harder to consolidate the tightness of the Cap and Septa. Since Aijiren’s automated merging of Cap and Septa machines is only suitable for the closure of 2ml autosampler vial, this large-volume closure requires manual combination by workers. Aijiren uses a dust-free workshop for production and packaging, so customers can be completely assured of hygiene issues.

Contact US

Get Price

Share:

Previous:

9mm Screw Neck Closures

Content

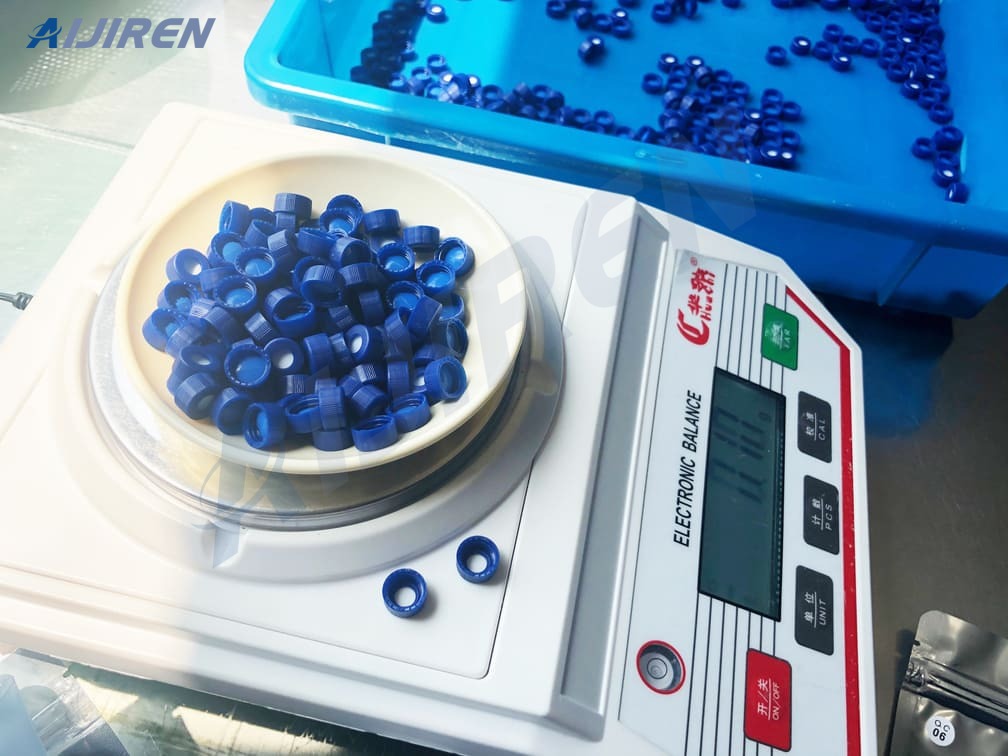

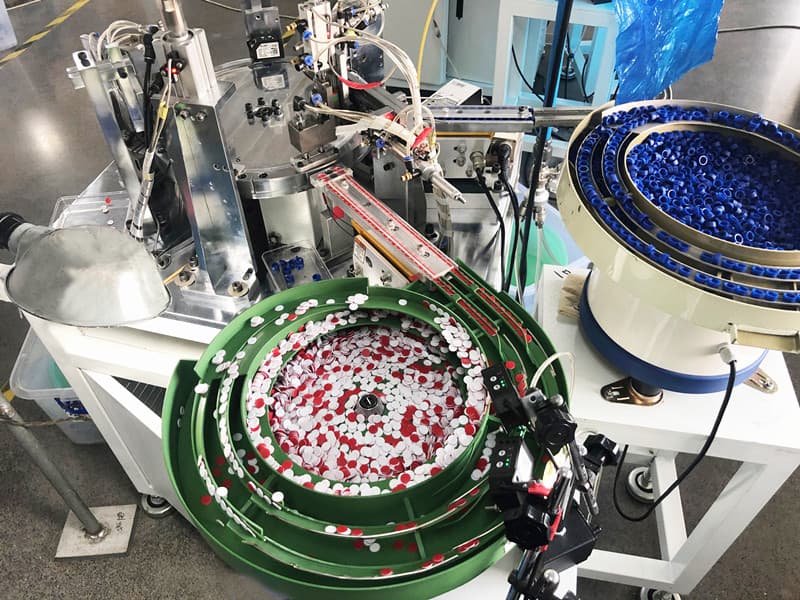

However, Aijiren produces 24mm Screw neck Cap and 22mm Silicone/PTFE using fully automated machinery. When mechanized production of Screw Cap is based on the mold, 6 Screw Caps are produced at a time, once every 3 seconds. This automatic production guarantees the output of 24mm Screw neck Cap. In the production of PTFE and Silicone, the two materials are compounded using an exclusive compounding process. Then, an automatic cutting machine is used to cut Septa into wafers of the same size. The final compound is 24mm Screw neck Closures.

The following video shows the production process of 9mm screw neck closures. The production steps of 24mm screw neck closures are similar.

The 24mm Screw neck Closures produced by Aijiren use high-quality polypropylene as the raw material. The larger central hole is also to facilitate the injection or sampling of the injection needle. The thickness of the Septa of 3mm can ensure sealing and will not cause the sample to leak or be in the air. Of impurities fall into Vial. As a professional production factory, Aijiren has many production workshops, professional Septa workshop, raw material workshop, Cap workshop, merger workshop, Via production workshop, printing workshop, packaging workshop, storage workshop and so on.

Inquiry

More Workshop