Autosampler Vial Septa Workshop

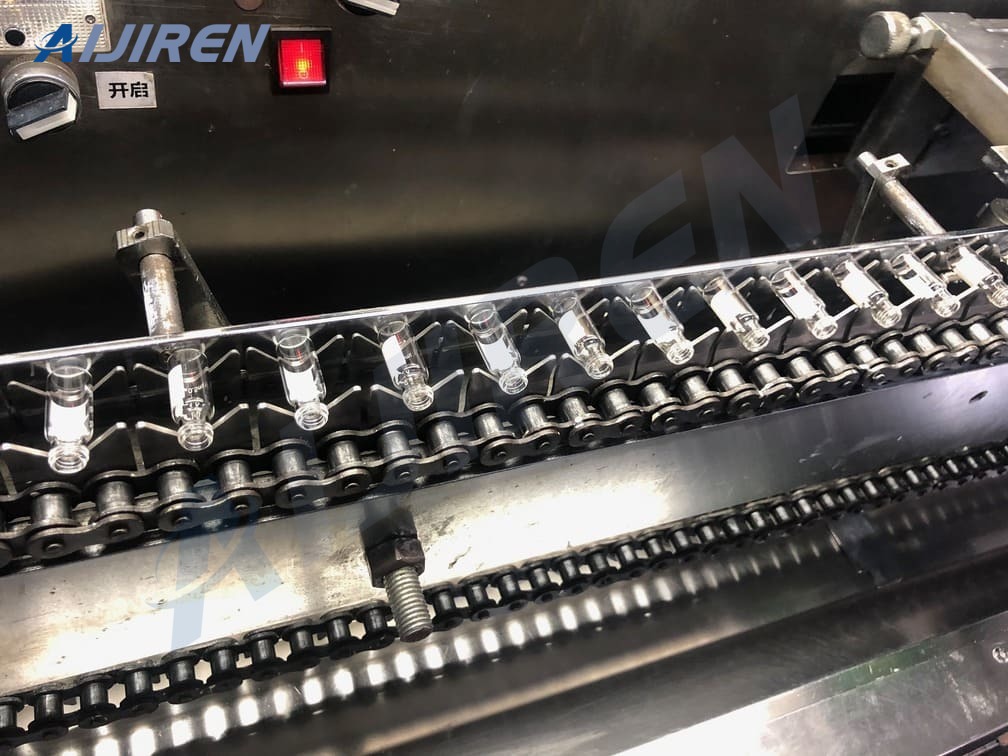

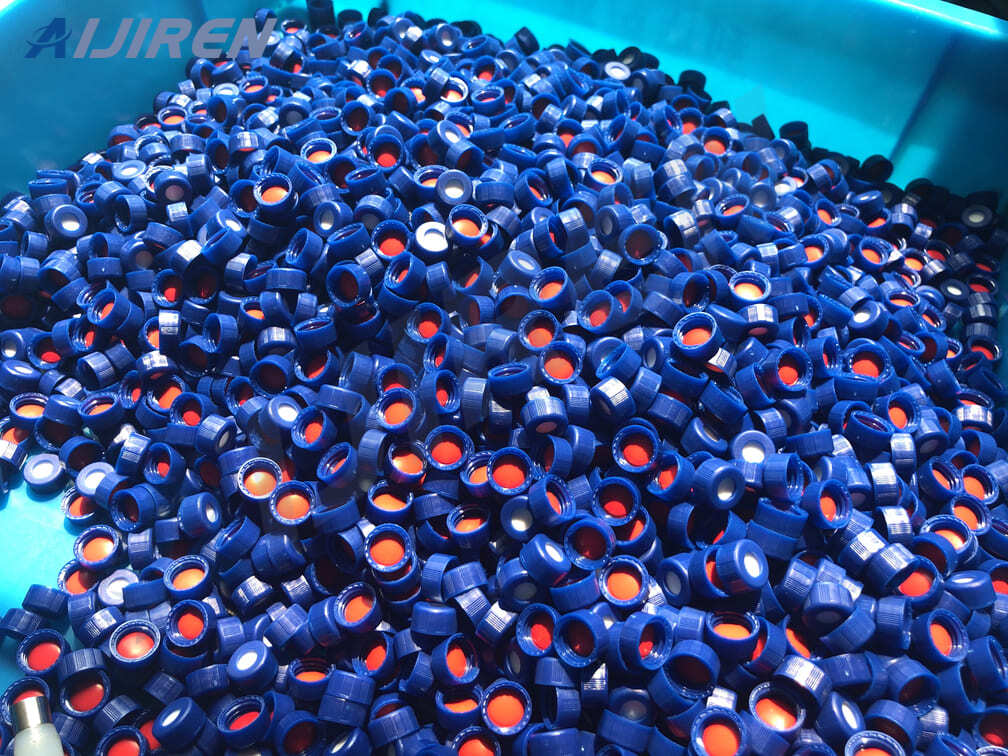

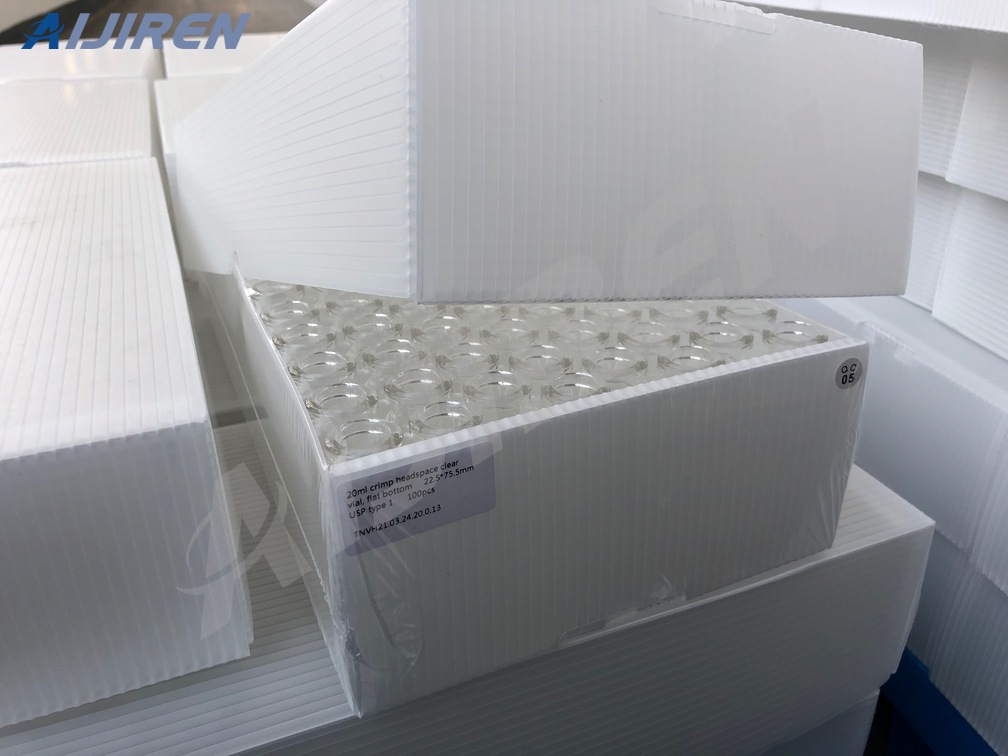

Aijiren is a production-oriented enterprise with its own production plant and production workshop. Aijiren is committed to producing Autosampler Vial and its supporting Cap with Septa. Aijiren uses high-quality raw materials to produce Septa. The raw materials are free of impurities and pollution. They are processed in a dust-free workshop. Customers can buy with confidence, Aijiren supports factory inspection, welcome to Aijiren.

Contact US

Get Price

Share:

Content

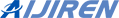

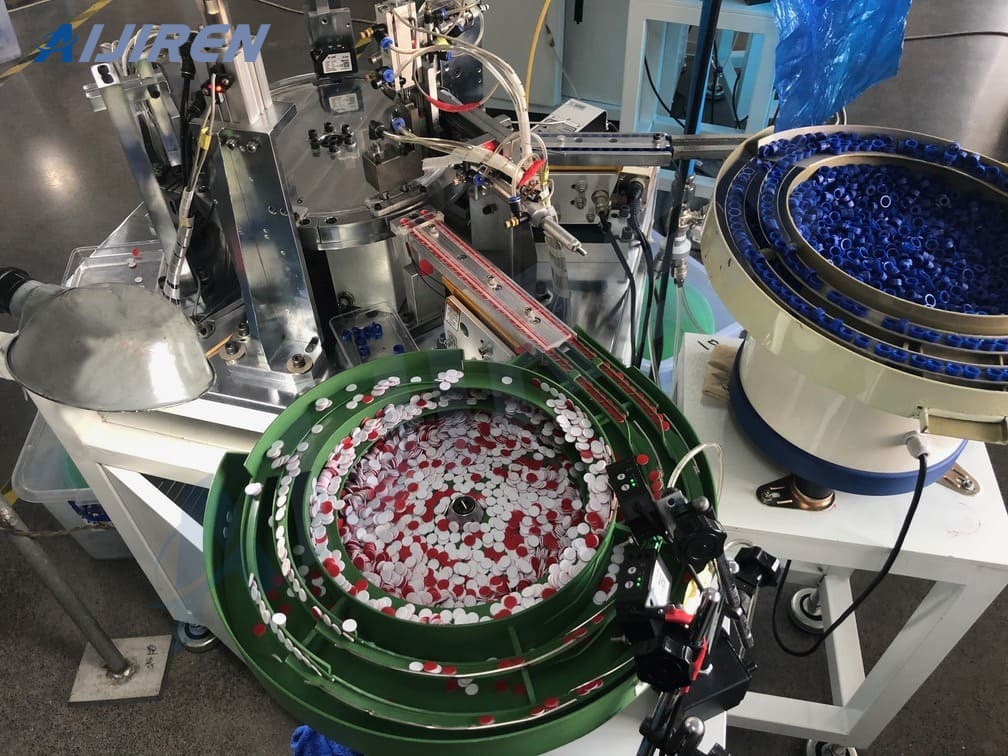

Aijiren has two workshops related to Septa production, one is the compound workshop of Silicone and PTFE, and the other is the cutting workshop of Septa. The picture shows the cutting workshop of Septa. After compounding, Septa is neatly coded on the container, waiting for the machine to cut them into wafers of the same size for Autosampler Vial. Generally speaking, the side of Septa’s PTFE faces the reagent inside Via. Because PTFE is inert and will not react with reagents, and Silicone has to ensure the elasticity and recovery of Septa, Aijiren uses a binder-free method to produce Septa.

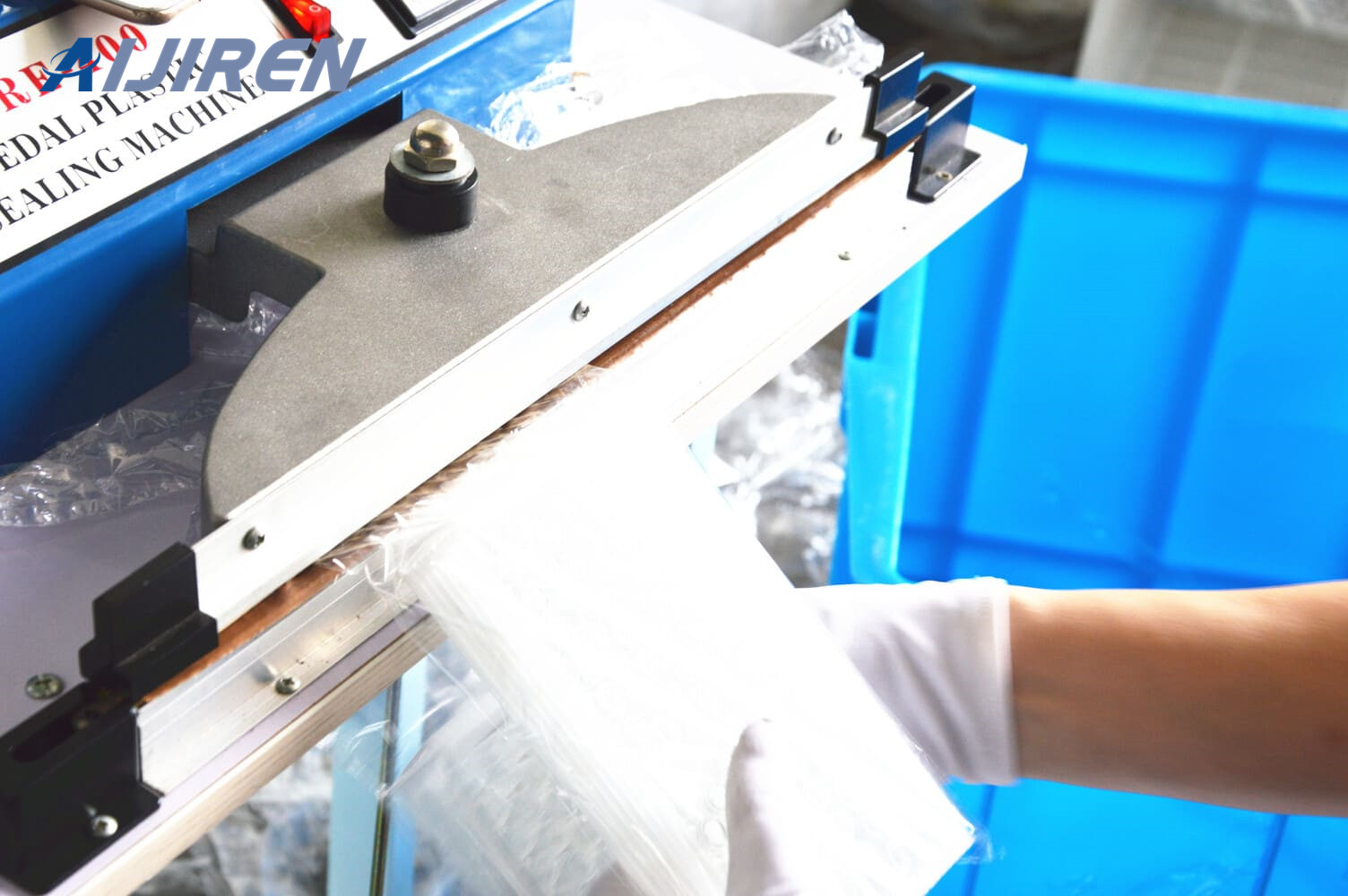

The important role of Septa is to help the Cap to seal and protect the sample. At the same time, when the automatic injection needle is punctured, it is smoothly pierced without losing the sealing performance. This has higher requirements for Septa. Aijiren is for different automatic injection needles. Different types of Septa are produced. If it is a thin and sharp auto-injection needle, it can pierce Septa smoothly. If it is a blunt and thick auto-injection needle, you can buy the Septa with Pre-Slit produced by Aijiren, the flat-shaped and cross-shaped Pre- Slit, the cross shape is more convenient and the opening is larger.

Inquiry

More Workshop