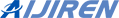

Aijiren Worker is Cutting Septa

As a factory specializing in the production of chromatographic consumables, Aijiren has hundreds of workers for production, especially Septa. Aijiren has exclusive septa composite technology, so the requirements for the workers in the septa workshop are very high. The workers in the picture are using cutting machines for Silicone and PTFE composite material for cutting work.

Contact US

Get Price

Share:

Previous:

Cutting 8mm PTFE/Silicone Septa

Next:

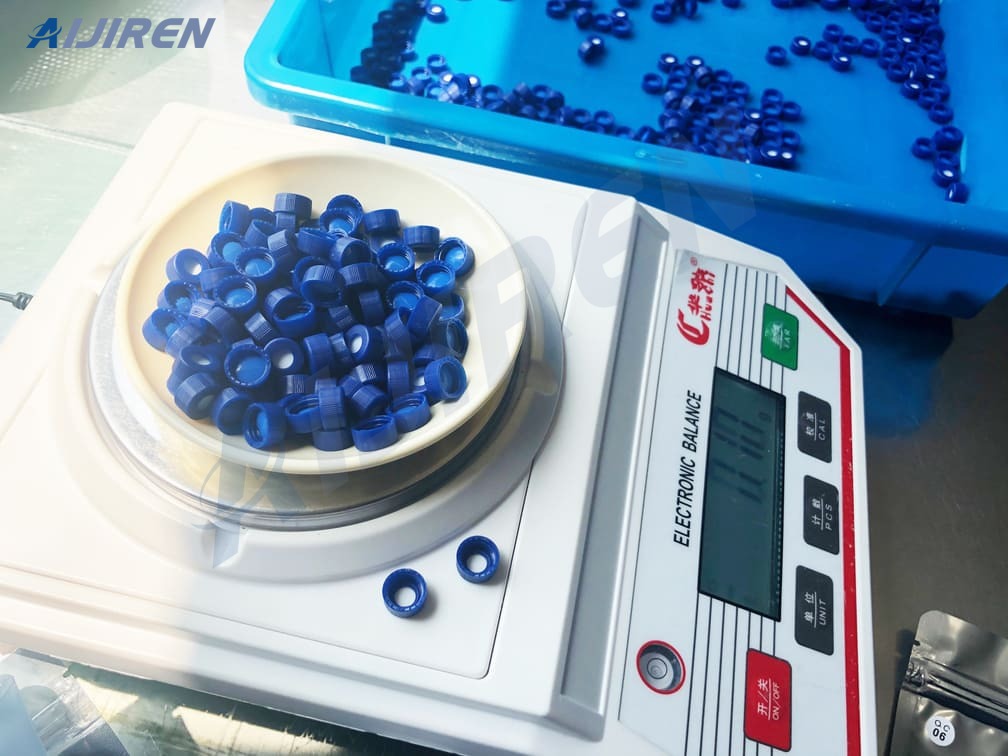

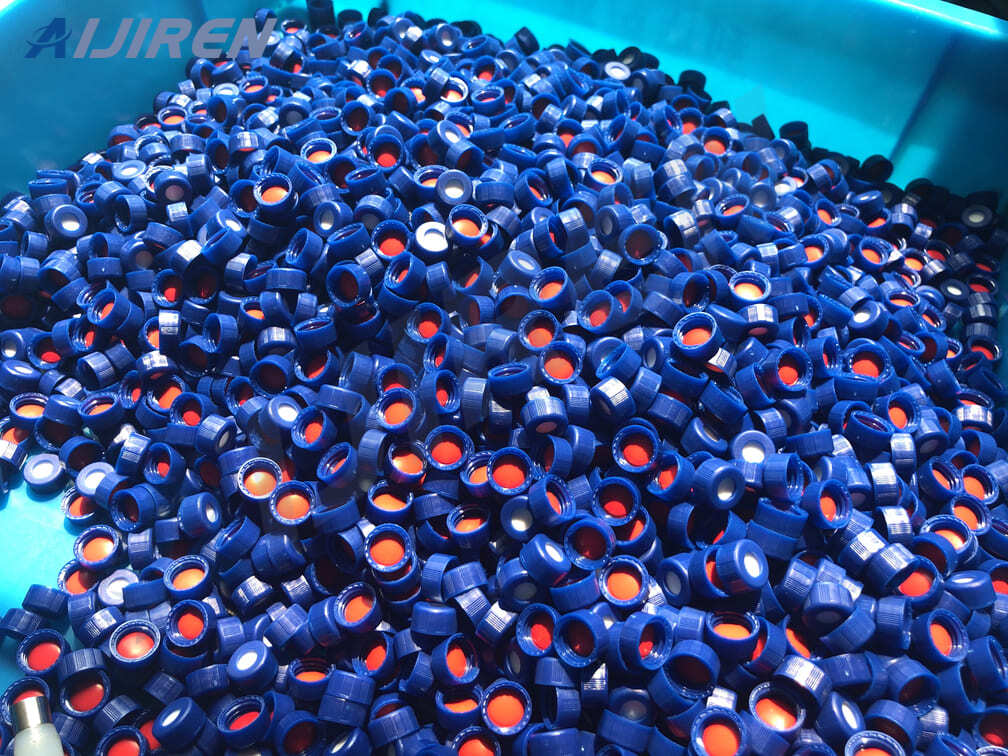

Screw Cap Mold Mading

Content

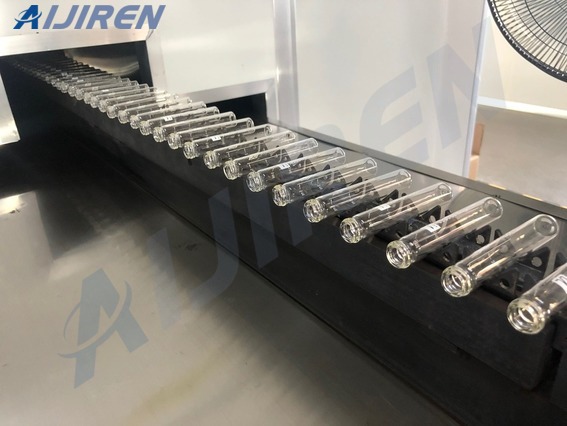

Aijiren, as a large-scale consumables manufacturer, has a large plant. In the plant just for the septa cutting step, there are 30 semi-automatic and fully automated machines. A large number of production machinery brings a lot of productivity, and the workers operate semi-automatically. The machine cuts septa of the same size from the laminated silicone&PTFE material. Fully automated machine workers only need to fix the silicone&PTFE material on the machine, and the machine can complete automatic cutting. A worker can manage three to four machines at the same time, which greatly saves labor costs and improves production efficiency.

With its own technical advantages, Zhejiang Aijiren Technology Instrument Co., Ltd. has become the only manufacturer in China that independently produces Teflon/silicone gaskets, saving you the cumulative sales costs of middle-level distributors, and the price is more competitive. The strength and its own technical advantages provide reliable quality assurance for each batch of products shipped out of the factory, so that customers can use it with more peace of mind.

Inquiry

More Workshop